ASIK CONSULTANCY will also give consulting services to the designs, drawings and

projects it has produced or contributed. Product management consulting service

includes:

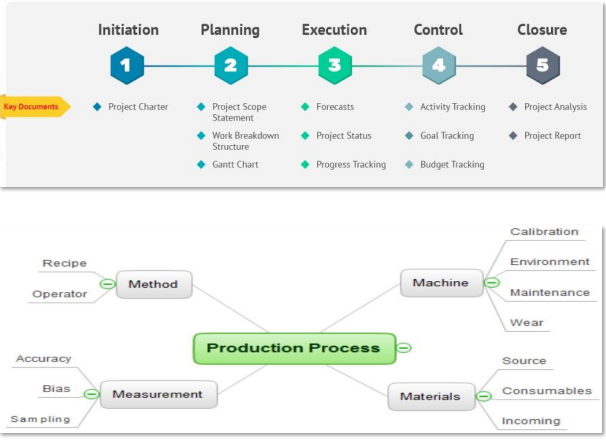

• Using programs to follow up the projects steps correctly.

• Organization of kick of the projects meeting.

• Defining the project missions and objectives,

• Creating the work breakdown structure, gantt chart and defining the

project milestones.

• Assigning the KPI’s to their target and those responsible

• Defining the communication plan and communication plan’s period.

• Creating risk assesment chart for projects.

• Reporting daily progress for project sponsors.

• Tracking the daily task lists and assinging those responsible.

• Creating meeting plans and reporting the meeting notes.

• Keeping up to date with any policy and legislation changes.

• Managing the changes of during project.

• Monitoring project budgets.

The production processes are managed in order to ensure that the production

companies take the steps to eliminate their inefficiency by reviewing their production

activities. As a result, the activities that effect the productivity is reviewed and

determined.

The goal of the managers in the production system is to work in harmony between

people, materials and machines, and to work economically and efficiently. Compliance

and efficiency can be established through regular planning and control.

ASIK CONSULTANCY support the company to increase productivity and quality.

Method

Within this framework, in production lines, ASIK CONTULTANCY’s activities: • Production line analysis • Improvement of production line • Formation of production systems • Assembly line analysis and improvement studies • Line analysis and improvement meetings • Sustainable progress of line’s work, • Creating process instructions, • Manual Tracking • Work study, Capacity Planning and Productivity Analysis, • Training the worker, • Defining the budgetMeasurement

Creating performance system for worker

• Defining the personel KPI’s according to company strategy

• Measuring product time and line losses

• Creating quality gates in lines and measuring the quality faults and

reporting

• Gathering the datas for line activities and documentation

• Measuring productivity